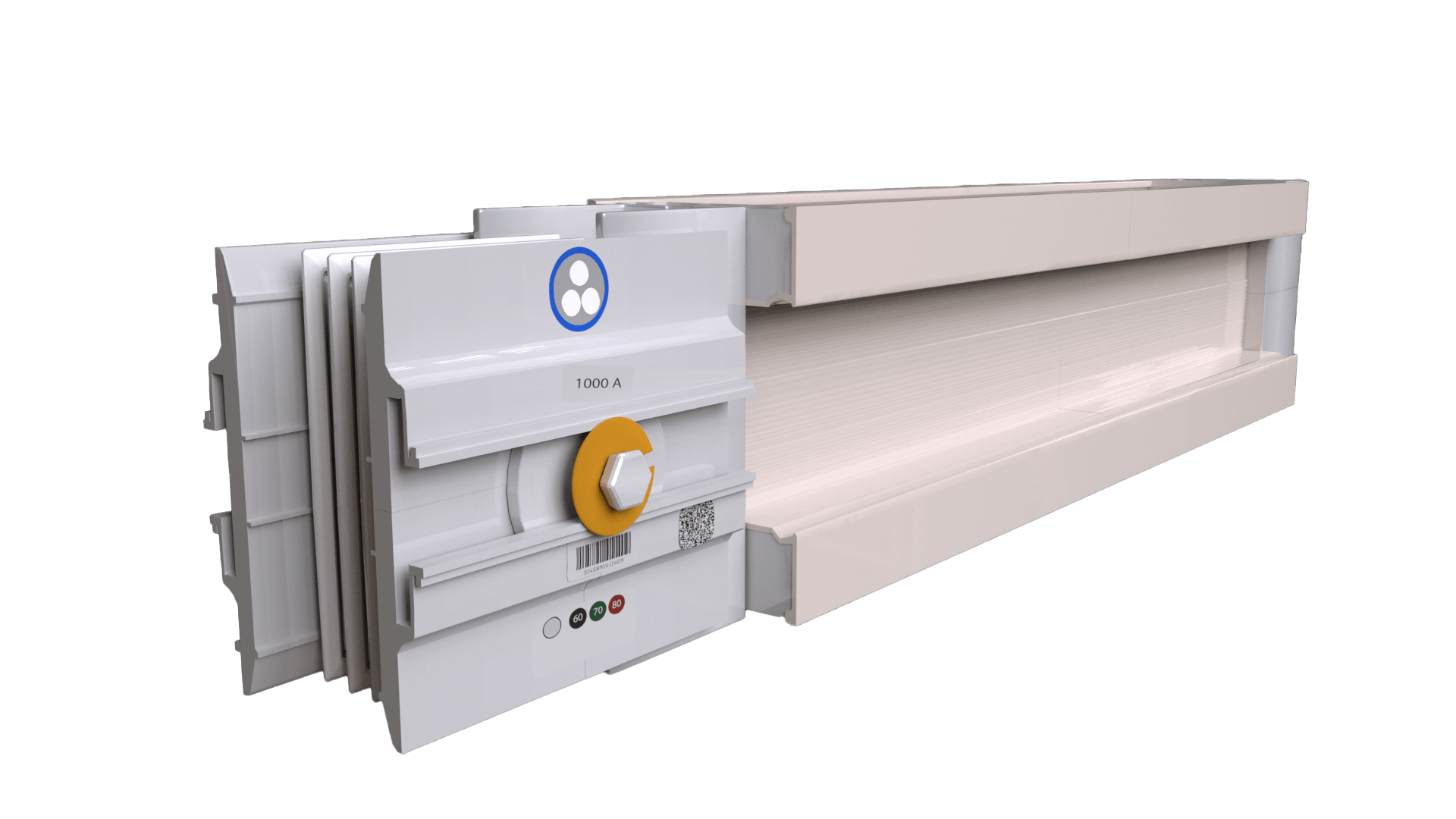

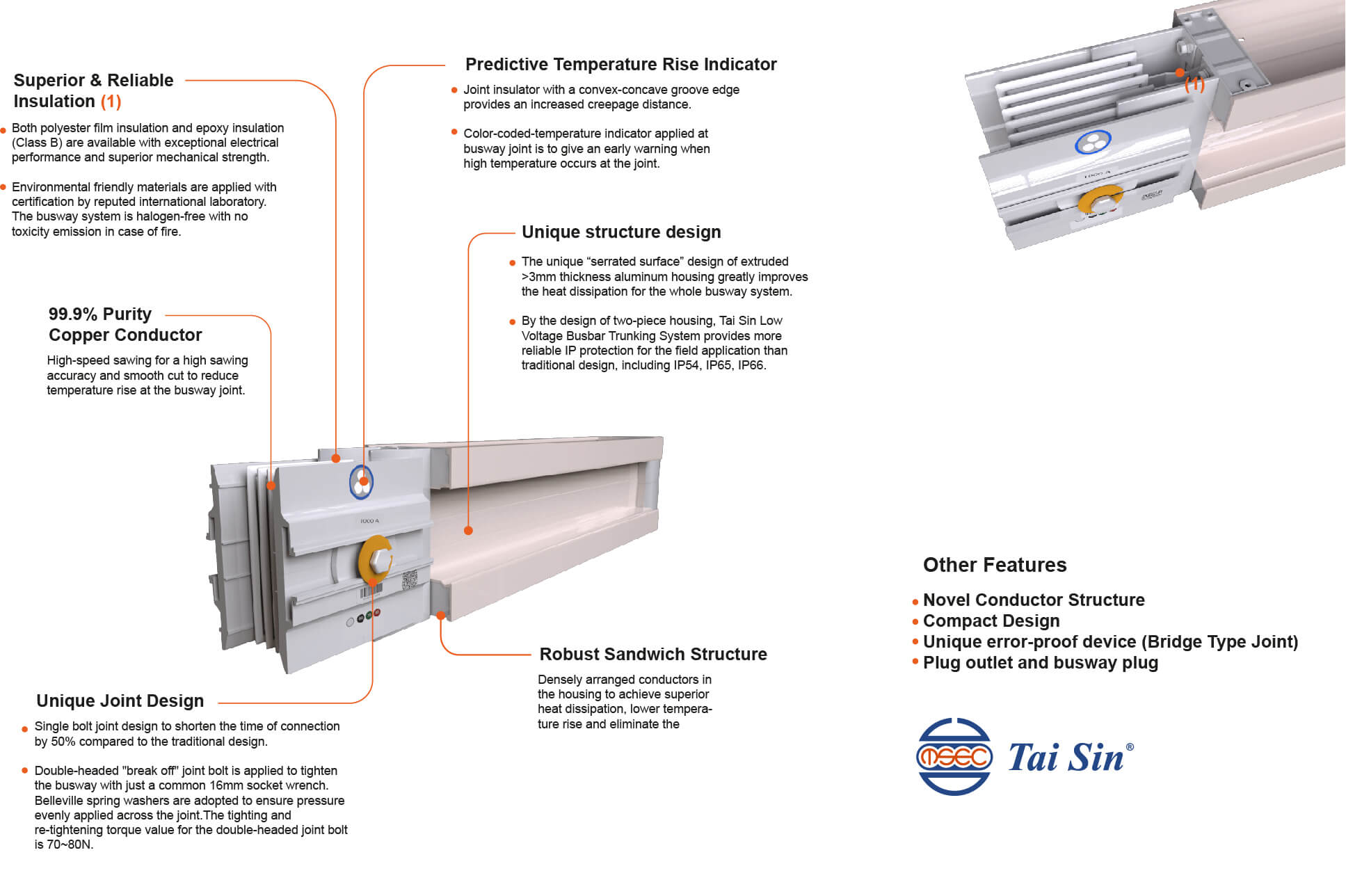

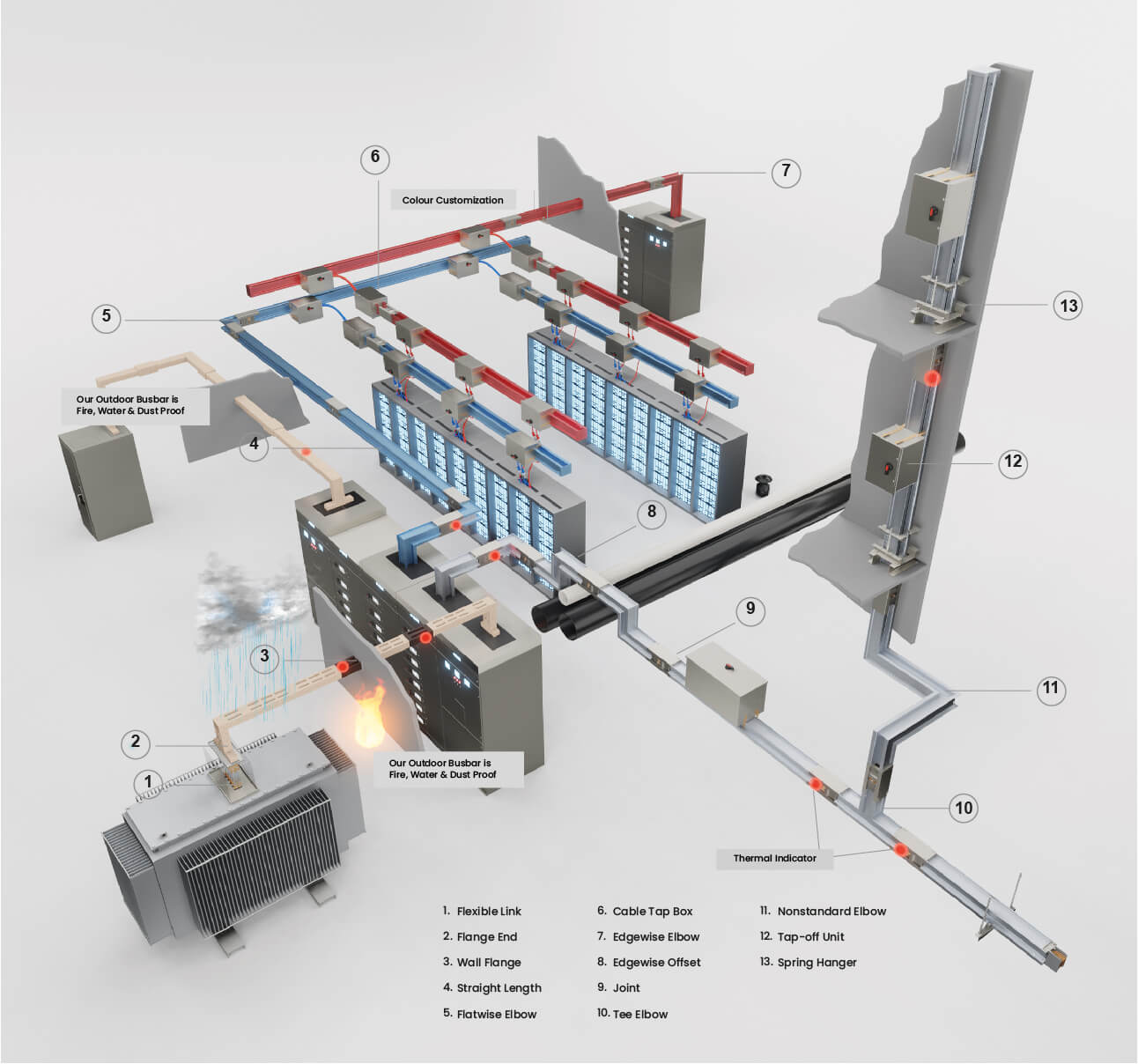

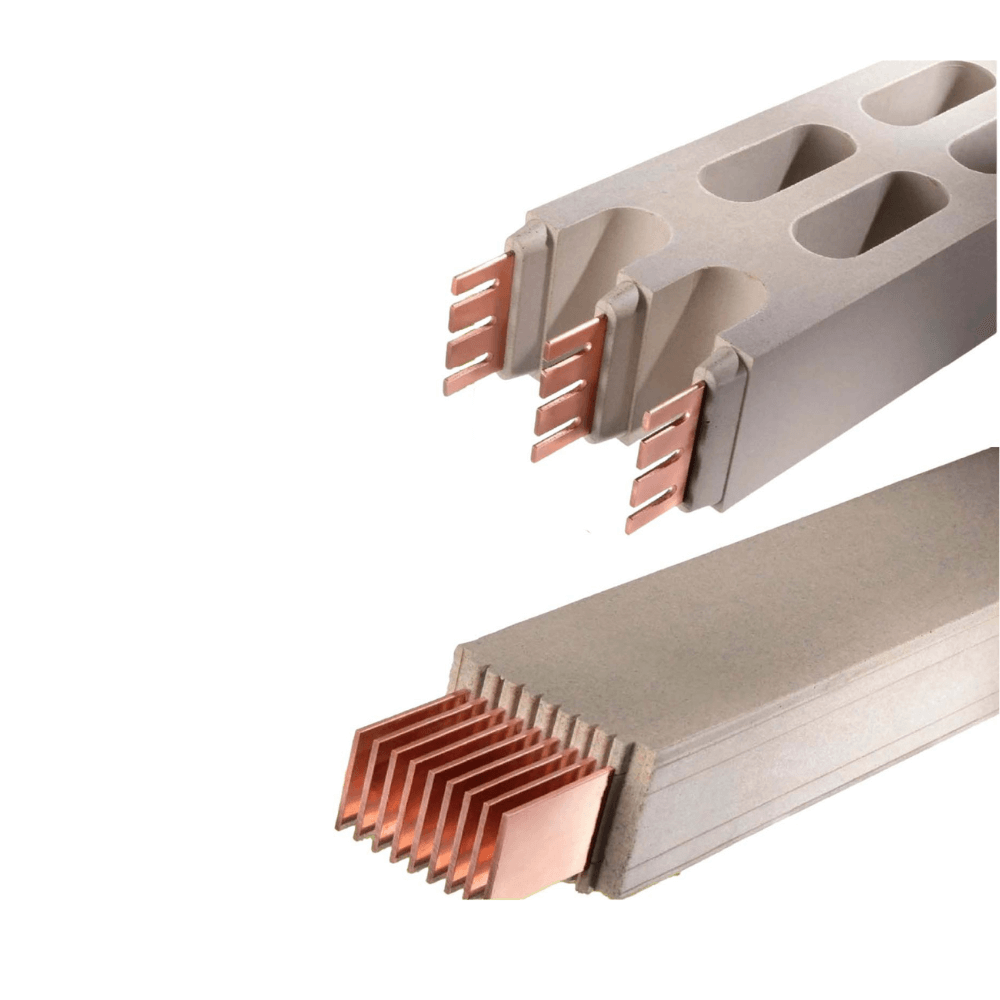

Tai Sin LT Line I Busbar Trunking System (a.k.a Busway, Bus Duct) is a reliable and efficient electrical distribution system with sandwich construction and superior performance. It is a safe and robust power distribution system with high electrical efficiency, low voltage drop, high mechanical strength.

Our system offers a full line of busbar trunking system to meet most requirements. Offering 3P3W, 3P4W, 3P5W, supply and distribution, with rated current from 250A to 4000A (for aluminum conductor) & 400A to 5000A (for copper conductor), rated operation and insulation voltage up to 1000V, IP degree up to IP66 and the frequency 50~60Hz.